Last updated 5/2024

MP4 | Video: h264, 1920×1080 | Audio: AAC, 44.1 KHz

Language: English | Size: 2.61 GB | Duration: 5h 1m

CP design fundamental ,Cathodic Protection Criteria, Galvanic (Sacrificial) anodes systems, Impressed Current Systems

What you’ll learn

Corrosion Introduction

Driving Force for Corrosion and The Pourbaix Diagram

Reference Electrodes types and uses

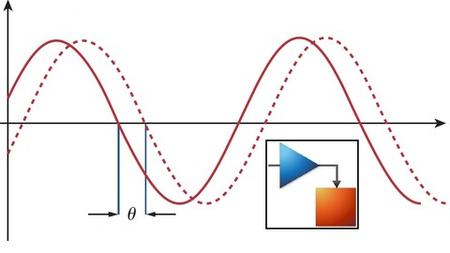

Corrosion Cell Kinetics (Polarization) definition , factor affecting and Evans diagram

Cathodic Protection Criteria

Galvanic (Sacrificial) anodes systems

Impressed Current Systems

CP Design Fundamentals and 2 case study

Requirements

student, Engineering, technicians, fresh graduate , cathodic protection operator

Description

Corrosion is one of the most important problems encountered by the owners and operators of underground, offshore, submerged and other metallic structures exposed to an electrolyte. If corrosion is not controlled, it can lead to large costs in repairs or facility replacement. Even greater costs can be incurred from environmental damage, injuries and fatalities.Corrosion control personnel must have a good basic understanding of corrosion mechanisms. They also need to know the various conditions under which corrosion can occur on underground facilities. In this course, we will focus on the control of metallic corrosion by applying cathodic protection. This course was developed for cathodic protection field technicians, although this knowledge is also needed by corrosion engineering personnel. Cathodic protection (CP) is a corrosion-control technology that involves making a metal surface the cathodic side of an electrochemical cell. Connecting the metal to be protected with a more readily corroded metal to act as the anode of the electrochemical cell is the easiest way to apply CP. In theory, cathodic protection can be used to protect any metallic structure in contact with a bulk electrolyte. However, it is most commonly used to protect steel structures buried in soil or submerged in water in practice. Cathodic protection systems protect a variety of metallic structures in various situations. The most prevalent are water and fuel pipelines, storage tanks, ships and boats, offshore oil platforms, oil well casings, and other applications. This chapter will go through the fundamental principles of cathodic protection and current advancements in the field.

Overview

Section 1: Introduction

Lecture 1 Introduction

Section 2: Corrosion Introduction

Lecture 2 Corrosion Introduction

Lecture 3 Driving force for corrosion

Lecture 4 Reference Electrode

Lecture 5 The Pourbaix Diagram

Section 3: Corrosion Cell Kinetics (Polarization)

Lecture 6 polarization part1

Lecture 7 Polarization part2

Lecture 8 Polarization part3

Section 4: Cathodic Protection Criteria

Lecture 9 Cathodic Protection Criteria part1

Lecture 10 Cathodic Protection Criteria part2

Section 5: Cathodic Protection Systems

Lecture 11 Galvanic (Sacrificial) anodes systems

Lecture 12 lecture 7 part 2 (Galvanic (Sacrificial) anodes systems)

Lecture 13 lecture 8 ( Impressed current system)

Section 6: Cathodic Protection Design Fundamentals

Lecture 14 CP Design Fundamentals part1

Lecture 15 CP Design Fundamentals part 2

Lecture 16 CP Design Fundamentals part3

Lecture 17 CP Design Fundamentals part4

Engineer and technician working in Cathodic Protection Corrosion Control System

Homepage

https://anonymz.com/?https://www.udemy.com/course/cathodic-protection-corrosion-control-system/