Published 7/2024

Created by Tom Moore Moore

MP4 | Video: h264, 1280×720 | Audio: AAC, 44.1 KHz, 2 Ch

Genre: eLearning | Language: English | Duration: 12 Lectures ( 1h 20m ) | Size: 845 MB

An introduction

What you’ll learn:

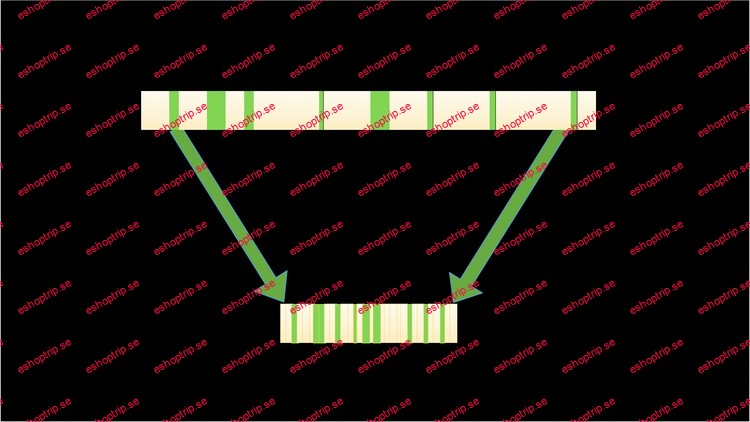

Understand what a Value Stream Map (VSM) is

Understand what makes a VSM for knowledge processes different than manufacturing

Understand how to create a visual AS-IS VSM for knowledge processes

Understand what AS-IS data to collect and how to get it for a VSM

Understand what the data and calculations tell you about your process

Understand what improvements are possible and the benefit in a to-be VSM

Requirements:

Awareness of Value Stream Mapping

Familiar with basic process mapping methods

Description:

Value stream mapping for knowledge processes involves visually mapping out the flow of information and tasks required to complete a knowledge-based activity, identifying all the steps from initiation to completion. This helps in pinpointing inefficiencies, bottlenecks, and areas of waste, such as unnecessary approvals or redundant data entry, which can be streamlined for improved productivity. By focusing on enhancing the flow of knowledge and reducing delays, organizations can optimize their processes, leading to faster, more effective decision-making and better overall outcomes.This course is intended for people who manage a knowledge process, are charged with improving a knowledge process, or responding to customer issues, or management needs. They can have many different roles. The course describes and shows how value stream mapping is used to understand and improve a typical knowledge process.The participants will learn what a value stream is for a knowledge process and the components of a value stream map for these processes. After that, the participants will learn how to construct an AS-IS value stream map and how to collect the data for activity time, elapsed time and percent accurate and complete.Using these data, they will learn how to calculate the key performance measures of process efficiency, process effectiveness (or rolled throughput yield), and lead time. They will go through the step of identifying value add and non-value add steps in the process.They will see how to identify the process bottleneck using a simple approach.Once the performance measures are explained, the participants will learn the many ways a process can be evaluated for improvement. These are Eliminate waste, reduce lead time, increase quality, and increase throughput. Each of these methods are explained as well as how to get the specific information needed for each.Next is to take the potential ideas to improve the process and apply lean methods of process improvement, which can include error proofing, standard operations, one piece flow and kanban systems. A method to evaluate which of the many ideas are more viable and impactful. is presented. This course wraps up with the TO-BE value stream map and the improved process performance measures. Managing the transition to the improved process is presented.

Who this course is for:

Business process owners

Business analysts

Agile product owners

People needing to improve an existing business process

People interested in learning how to analyze a business process

People who want to understand what value stream maps are and how they are used

Homepage